Page 1 of 1

Make Your Own Moulding

Posted: Sun 17 Jan, 2016 10:56 pm

by prospero

I needed a deep moulding to allow a spacer of 35mm. Didn't have anything handy so....

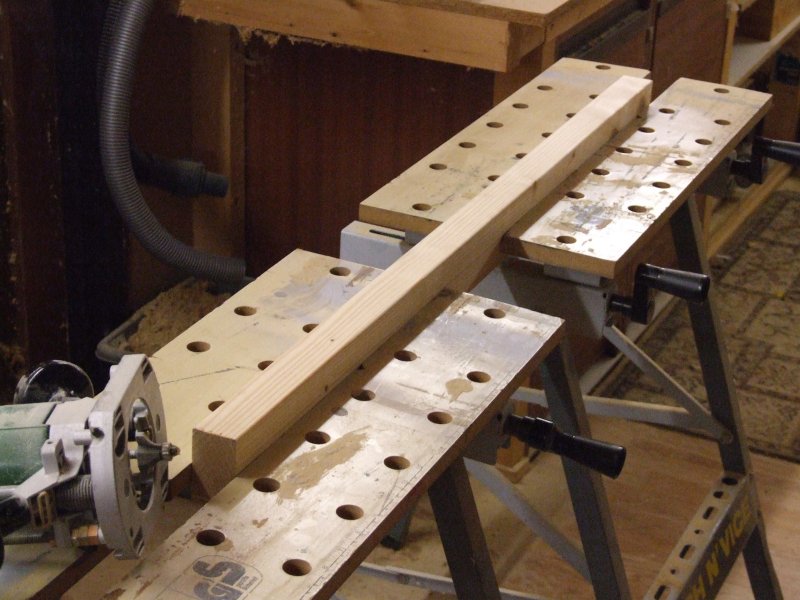

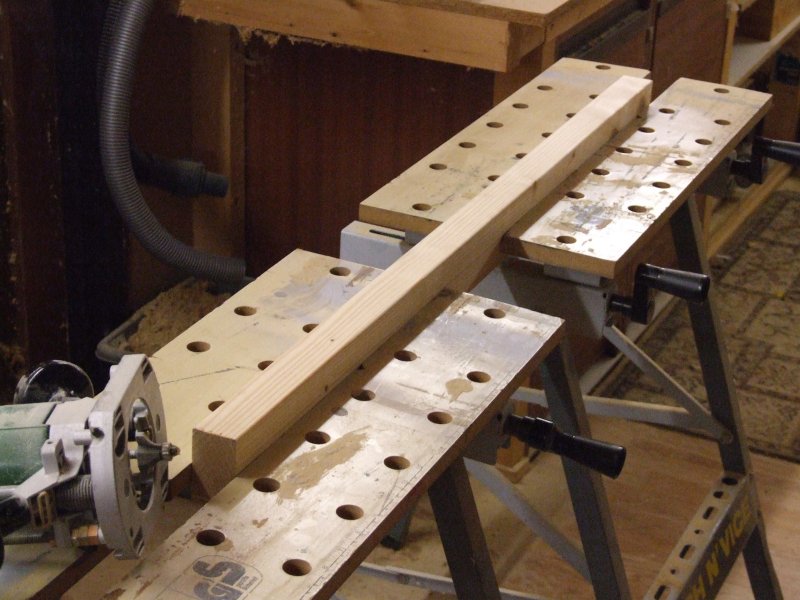

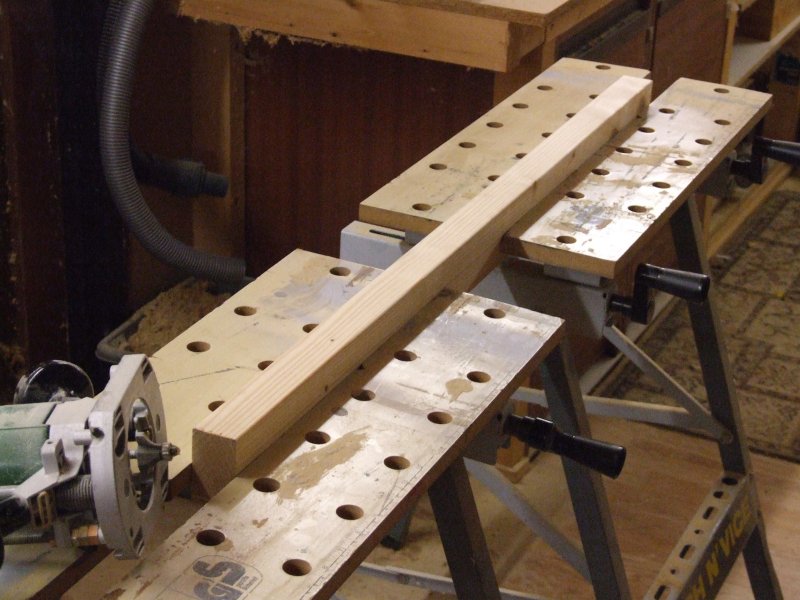

Go to Wickes and get an 8ft length of 63m x 34mm studding. Clamp it down and get out the router fitted with a half-rounding bit.

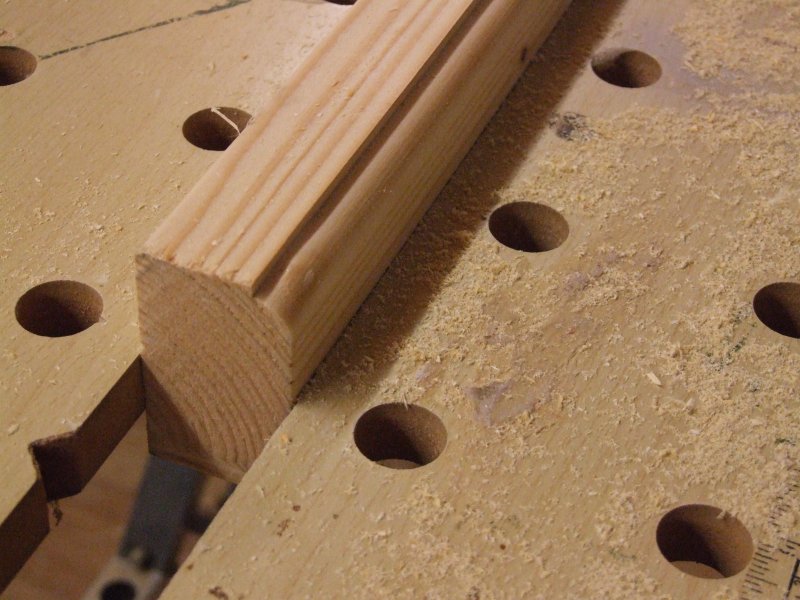

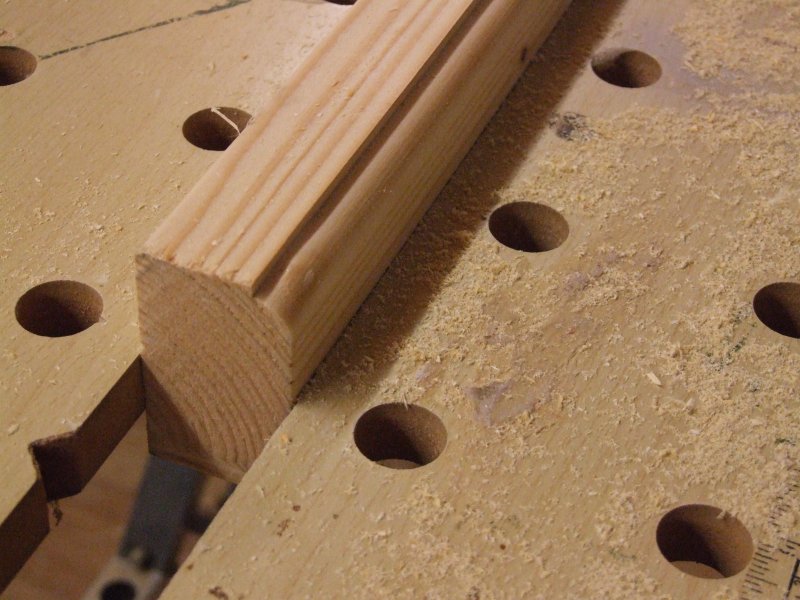

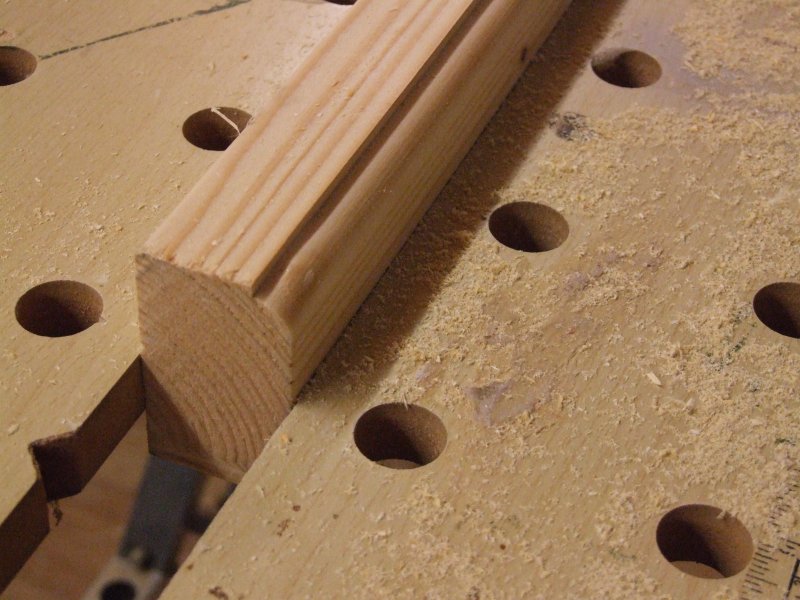

Cut along one corner.

Set Table saw to chop out a rebate 12mm wide and 47mm deep.

Here I've done the shallow cut. I did the deep one in two passes, increasing the blade depth for the second.

My table saw is strictly the cheapo DIY variety. If you have pro kit you would do it in one.

Slightly out-of-focus results.

The bit that came out of the rebate ripped down to 35mm. This will be the spacer in the frame.

After this I roughed up the outer surfaces with a wire brush to give the 'driftwood' effect.

I have the frame assembled and working on the finish.

Watch this space.....

Re: Make Your Own Moulding

Posted: Mon 18 Jan, 2016 10:38 am

by Jamesnkr

prospero wrote:Go to Wickes

Pathetic lack of self-reliance, Prospero. You should be ashamed of yourself!

Re: Make Your Own Moulding

Posted: Mon 18 Jan, 2016 10:50 am

by StevenG

Prospero....... again

Really! Does your ability meter even have a measurable stopping point

Re: Make Your Own Moulding

Posted: Wed 20 Jan, 2016 3:38 pm

by prospero

Coat of shellac. Coat of dark brown. Coat of white. Quick sand and wax. Bingo.

Re: Make Your Own Moulding

Posted: Wed 20 Jan, 2016 3:43 pm

by vintage frames

That is good, very good.

Re: Make Your Own Moulding

Posted: Wed 20 Jan, 2016 4:48 pm

by Jamesnkr

Crazy!

Why the shellac?

Re: Make Your Own Moulding

Posted: Wed 20 Jan, 2016 6:20 pm

by Fellows Framing

Great frame and fish.

Re: Make Your Own Moulding

Posted: Wed 20 Jan, 2016 7:25 pm

by prospero

The shellac is mostly to seal the knots in case they ooze at a later date. I managed to get them mostly on the sides though. It also helps paint adhesion on fresh cut wood.

Re: Make Your Own Moulding

Posted: Wed 20 Jan, 2016 7:57 pm

by Jamesnkr

Thanks.

Re: Make Your Own Moulding

Posted: Wed 20 Jan, 2016 8:08 pm

by StevenG

And as if by magic....... That's a great looking end product. Really good

Re: Make Your Own Moulding

Posted: Wed 20 Jan, 2016 10:07 pm

by Not your average framer

Nice job!

Re: Make Your Own Moulding

Posted: Wed 20 Jan, 2016 10:57 pm

by prospero

Didn't take long either. Most of the time was setting up the guides on the saw. If you were doing a quantity you could knock it out rapido.

The stick of wood was 2.99.

I only paid a tenner for the router.

Re: Make Your Own Moulding

Posted: Sun 24 Jan, 2016 10:57 am

by Framie

Looks great

When I first started framing I made all my own mouldings with lots of different shaped router cutters.

Lots of fun but after the first year I had became a nightmare (short of space) and I work from home.

Still do the odd job from scratch

Re: Make Your Own Moulding

Posted: Sun 24 Jan, 2016 1:55 pm

by prospero

If you are doing a 'rustic' finish then you can get by with relatively simple tools. I little wiggle here and there is not important and may even add to the overall effect. The main thing is to get your work fixed down firmly. The pair of workmates (7.50 each from Screwfix) makes an ideal setup for clamping long timbers. On the table saw I added various improvised guides so that the timber is kept on the right track and minimal hand guidance required. Sometimes, routing a groove or rounding an edge makes a plain piece into something a lot more appealing.

For finer work using nicer woods you really need a better table saw than the one I have. A router table would be better than doing it hand-held. Other useful kit would be a bandsaw and a planer/thicknesser. These will allow you to work on better woods and produce finer finishes. These machines take more space up though.

With these machines you can do a great deal. But they will have their limits. For instance, if you want to mill a big scoop. Some profiles are beyond the capabilities of most DIY woodworking gear.