Page 1 of 2

Bracing a Large Frame

Posted: Fri 15 Apr, 2016 3:27 pm

by joh5nny

I've just finished a large frame (roughly 1.2m square) using a moulding that's relatively deep but only about 20mm wide. I've added L plates at the corners to strengthen the frame, but there's a small risk of the long sides of the frame bowing and the glass popping out, even though the tape that covers the back of the frame and the backboard is doing a reasonable job of pulling it all together.

The frame is fine with careful handling, but I'd like to make it a bit more secure. I know that Lion sell a frame strap, but they're currently out of stock and it's not due back in until mid-May. Does anyone know of an alternative supplier who has such a thing or an alternative way of achieving the same end? Thanks.

Re: Bracing a Large Frame

Posted: Fri 15 Apr, 2016 3:31 pm

by Graysalchemy

if its relatively deep why not make a sub frame to fit on the inside strengthening it .

Re: Bracing a Large Frame

Posted: Fri 15 Apr, 2016 3:41 pm

by markw

As Graysalchemy says - a subframe will do the job - you could also crossbrace the corners on the subframe. A subframe is always a better solution than a strap as a strap can bend a flimsy moulding in. if you are really pushed for space then a brace made from a aluminium strip would also work - cutting to length then drilling the ends - screwed into the frame that would stop any bowing. The cheap way - fix d rings to the frame and use a strong wire tensioned between them - again a chance it will bow in.

Re: Bracing a Large Frame

Posted: Fri 15 Apr, 2016 4:28 pm

by joh5nny

Thanks for the input. A sub-frame sounds like the way to go. Might sound like a daft question, but what's the best way to secure it - just suitably sized screws through the sub-frame and into the outer frame?

Re: Bracing a Large Frame

Posted: Fri 15 Apr, 2016 5:38 pm

by GeoSpectrum

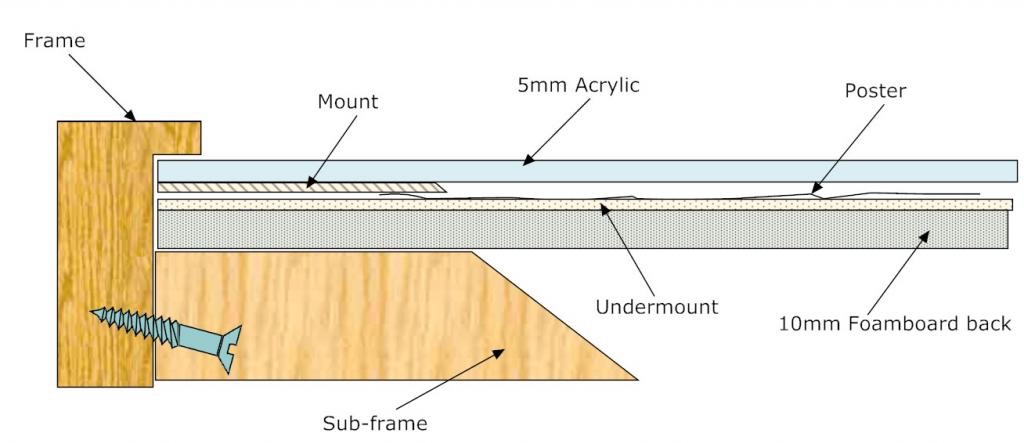

That's the way I use subframes.

- image.jpg (70.56 KiB) Viewed 10000 times

Image courtesy of Richard Christie

Re: Bracing a Large Frame

Posted: Fri 15 Apr, 2016 6:22 pm

by Graysalchemy

With hind sight the simplest solution is simply don't allow the customer to choose a flimsy frame. That's why I do, you are the expert at the end of the day so they should listen to you advice.

Re: Bracing a Large Frame

Posted: Fri 15 Apr, 2016 9:02 pm

by Not your average framer

Has anyone done the maths here? If the frame moulding is 20mm wide and the rebate width of the frame is perhaps 6mm, then the thinkness of the part of the frames to screw into to secure to the subframe is only 14mm. I hope the 20mm wide moulding is made from a reasonably solid wood, because you are not able to get a great deal of depth for the penetration of the screw and the tip, or sharp end of the screw is the most narrow part of the and has much less depth of thread as well.

Let's say that you can safely fit a screw into perhaps 10mm of this 14mm thickness and the taper on the screw diameter results in 6mm of the screw into the moulding being less than the normal thread depth on the remainder of the screw thread, then it might be very easy for the screw to strip out the wood into which the screw is inserted, without feeling all that much resistance on the screw driver.

It is at this point when you start to realise that the quality of the wood could make more difference than it at first appears and that there is plenty of reason why experienced framers prefer to use more substantial mouldings when framing larger frames. Also, when joining the corners on such a size of frame, how much strength and rigidity is there going to be for handling the frame while handling and fitting out the frame when the moulding is so narrow?

If it's cheap grade of obeche, which could easily have the odd unwanted soft spot where the screws find little grip, or the corner wedges don't produce the best and most secure joint, I'm not so sure that I would go for such a narrow frame on such a large frame even if it has a subframe. Personally, if it was my customer who wanted a 20mm wide moulding for such a size of frame and I could not talk them out of it, then I would be wanting the moulding to be something much stronger the obeche.

My original training was as a design engineer and design engineers are always aware of the lack of full thread depth, because it's one of the things they are expected to know about. Therefore adequate mechanical engaugement of the first few turns of a woodsrew, or self taping screw, compared to the remaining full diameter of the rest of the screw is important to consider. Be warned and in future, do the maths and work out if there is enough depth for adequate screw engagement to rigidly secure the subframe. Larger frames often need belt and braces construction!

BTW, subframes are good practice is such situations and I frequently employ subframes is similar situations.

Re: Bracing a Large Frame

Posted: Fri 15 Apr, 2016 9:10 pm

by silvercleave

I would screw a sheet of mdf on to the back which would stop any bowing of the frame and hold it all rigid.

Drill sunken pilot holes just in from the edge of the MDF and before screwing on put frame tape around the edge with the sticky side up and stick to the bottom of the MDF so that when it is screwed on you can turn the tape in and cover the screw heads

Ian

Re: Bracing a Large Frame

Posted: Fri 15 Apr, 2016 9:19 pm

by IFGL

I have done that before Ian, it works but adds weight.

Re: Bracing a Large Frame

Posted: Fri 15 Apr, 2016 9:31 pm

by Not your average framer

Yes, it does add weight, but in the right situations it still may be a good way of fixing the problem. It can be quite cost effective too!

Also, It should be remembered that normal grades of MDF will absorb moisture from the air and soften, which mades them significantly more flexible with age, (but ability to support loads is less affected with age), so allow for this when choosing the thickness of MDF to screw to the back of the frame.

Specialist grades of MDF such as Masonite do not absorb moisture from the air, because they are bonded with high grade epoxy resin and do not suffer from the same issues.

Re: Bracing a Large Frame

Posted: Fri 15 Apr, 2016 11:34 pm

by prospero

I got the latest Wessex catalogue the other day and was interested to see that they sell dedicated sub-frame moulding.

Using a thin moulding on it's own is expecting too much. There is a limit to just how strong you

can make the joins, brace it how you like.

This is a subframe I made just under 6ft sq.

It's pine cladding with the 'tongue' side ripped off. Notice the half-lap corners.

Much stronger than mitres. No complicated woodwork involved. Just a lot of gluing and screwing.

The outer frame was in this case quite hefty stuff, but it would be all the same with a narrow but deep section.

Re: Bracing a Large Frame

Posted: Sat 16 Apr, 2016 6:46 am

by markw

You could fix the subframe using the tabs from the yellow fletcher gun- the ones with a hole in them. A few fired into the frame rebate and then screwed into the subframe. Of course the wisest comment so far has been don't let your customer choose an inappropriate moulding.

Re: Bracing a Large Frame

Posted: Sat 16 Apr, 2016 10:33 am

by louisesimon

Prospero Rose and Hollis do a sub frame moulding 9mm in depth for when there isn't enough depth for 18mm.

Re: Bracing a Large Frame

Posted: Sat 16 Apr, 2016 10:38 am

by Graysalchemy

The problem with just attaching an mdf panel to the back is that it doesn't support the front of the mitre the weakest part, and the the part supporting the weight of the glass. A sub frame supports the front on the frame better IMHO.

Re: Bracing a Large Frame

Posted: Sat 16 Apr, 2016 10:51 am

by prospero

Fixing a board to the back can work well in some cases but a big problem is that unless it is well sealed it can

expand according to the prevailing atmos. If this happens it will either bow out or break the corners.

The bigger the frame the more it will swell.

Re: Bracing a Large Frame

Posted: Sat 16 Apr, 2016 5:30 pm

by joh5nny

Thanks for all the suggestions. I think I'm going to take the sub-frame approach and like the idea of using the yellow Fletcher gun as a method of securing it. I accept the various comments about insisting on using a chunkier frame, but this is a customer that I do quite a lot of work for and who I like to try and help out. The frame is reasonably robust already, but I just want to go that little bit further to make sure the worst doesn't happen. I suppose the question is would I do the same again - let me think about it!

Re: Bracing a Large Frame

Posted: Sat 16 Apr, 2016 5:38 pm

by Graysalchemy

I wouldn't use the fletcher gun they are pants and only as strong as the two thing prongs going in less that 3mm into the frame. Far better to screw into the frame it will support it far better.

Good customer or not I would still advise against it. I have this week with a national chain of restaurants which give me a hell of a lot of work.

Re: Bracing a Large Frame

Posted: Sat 16 Apr, 2016 5:45 pm

by markw

Yes screws are stronger and if you have the depth fine. But the Fletcher gun does work in situations where you really don't have the depth. You just have to use a lot of them whereas you might only use a few screws.

Re: Bracing a Large Frame

Posted: Sat 16 Apr, 2016 6:42 pm

by Graysalchemy

I have never had any joy with a fletcher gun they are a bit to toy town in my opinion they never fire far enough in and tend to pull out on mass. If I wasn't going to screw then I would use narrow crown staples 15 mm from a pneumatic stapler.

Re: Bracing a Large Frame

Posted: Sat 16 Apr, 2016 11:48 pm

by markw

That would work